Experience at your service

For 64 years, EUROPELEC has been designing, manufacturing and installing equipment for the pre-treatment and treatment of municipal and industrial wastewater.

Leader on the French market, EUROPELEC exports its products in about forty countries from its factories located in France, near Paris.

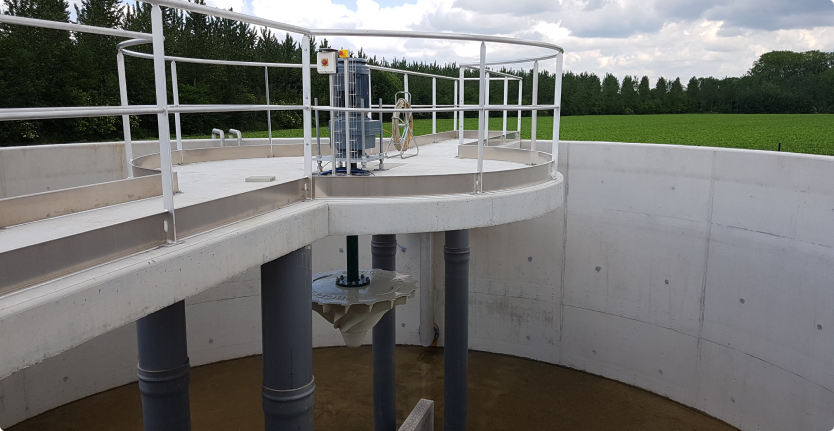

EUROPELEC has installed more than 10,000 aerators and more than 1,000 wastewater treatment plants equipped with fine bubble aeration ramps. The company provides its customers with a wide variety of solutions for wastewater treatment: bottom and surface turbines, fine and medium bubble diffusers, agitation, pre-treatment, metal frame equipment (scraper and suction bridge, thickeners, etc.).

EUROPELEC has the engineering capacity to size its equipment according to the needs of its customers and to carry out its own internal research and development programs.

In particular, the company has its own test basins and facilities for testing the performance and oxygenation capacity of its equipment in accordance with the NF EN 12255-15 standard.

All our products are manufactured in France in our factory located near Paris. Specialized in boiler making and mechanics, our production teams master a know-how that allows us to assure you quality products. EUROPELEC has the opportunity to count about forty people among its staff and tends to develop constantly!

The entire team is at your disposal to meet your needs for your municipal and industrial projects. Our sales team is composed of multilingual engineers, supported by our international network of agents and distributors

The engineers in charge of projects in our construction department are your privileged contacts to accompany you throughout the duration of your project.

Their knowledge and mastery of CAO-SOLIDWORKS software are assets to define and validate the design and studies related to your project.

Also trained in project management, your project manager monitors the production, delivery and installation of your equipment.

VA MASSAN – Sweden, IFAT – Germany, AQUATECH – Mexico, WEFTECH – USA, AquaNederland – Holland, Aquarama – Belgium, VIETWATER – Vietnam, SIEE POLLUTEC ALGER – ALGERIA.

EUROPELEC also invites you to visit national exhibitions such as POLLUTEC in Lyon or CARREFOUR DE L’EAU in Rennes.

The SFA Group was founded in 1958 and started with the design and construction of wastewater treatment plants. The SFA Group also developed in other sectors. Very quickly, in 1960, SFA revolutionized the sanitary equipment market by creating the famous Sanibroyeur and gradually left aside its water treatment activity.

64 years in the service of water quality

EUROPELEC has always produced its equipment in France, relying on its workshops near Paris, in Brégy in the Oise region, and on a network of French SMEs which ensure quality subcontracting while contributing to the development of employment in the country.

Today, more than 90% of EUROPELEC production is French and the company has chosen to reinforce this position by investing in the development of new production capacities on its historical site (1600 m² inaugurated at the beginning of 2020). Beyond the economic stake, the control of the production of components essential to the functioning of EUROPELEC equipments is a guarantee of their quality and their performance

With 64 years of experience and know-how, EUROPELEC sales teams and design office can advise you from the design phase on the solution best suited to your needs.

The company’s technical teams will then support you throughout your projects: technical advice, assembly or assembly assistance, rental, maintenance… are all services provided by EUROPELEC. Customer satisfaction is essential for EUROPELEC.

It is based on :

The protection of the environment is at the heart of EUROPELEC’s business, directly linked to the treatment and quality of water.

In order to go further in the protection of the environment EUROPELEC uses recyclable materials (steel, polypropylene, HDPE, EPDM,…) in the design and manufacture of our products

The constant search for improvements in the efficiency of aeration devices (Gross Specific Intake or GSI) also contributes to reducing energy consumption linked to water treatment and thus to protecting the environment.

EUROPELEC considers safety as a priority and regularly organises training courses for its employees to raise awareness of safety on the sites (risk prevention, work in purification stations, work in confined spaces, etc.), certification (CACES, etc.) or authorisations (working at height, etc.).

A French manufacturer for 64 years, EUROPELEC now offers its wastewater treatment equipment worldwide.

Relocation of its production to Brégy in the Oise region

90% of EUROPELEC equipment is 100% French

As of 2018, EUROPELEC has made the choice to relocate its production and to reinforce and modernize the capacities of its factory, located in Brégy in the Oise region. This decision is reflected in particular by the commissioning of a 1600 m² extension, inaugurated in early 2020.

Today, more than 90% of EUROPELEC’s equipment is 100% French.

All the boiler making and metalwork parts, in particular, are made in-house.

Some of the other components are manufactured by a few French subcontractors, whose production is controlled by quality plans that ensure the homogeneity and traceability of the parts leaving their factories. The control of the manufacture of components essential to the operation of EUROPELEC equipment allows us to guarantee a constant and high level of quality in production.

The know-how of our skilled workers (some of whom have more than 30 years of experience) is perpetuated through a recruitment and apprentice training program that has made it possible, in particular through exchanges with Promeo, the training center of the Union des Industries et Métiers de la Métallurgie (Union of Metallurgy Industries and Trades) – to recruit nearly ten young boilermakers, fitters and installers in 2018-2019.

30 years of experience for some of our employees

Young people qualified in boiler making, assembly and installation

Reliability of our equipment

All our plastics and polymers are recyclable

All our steels are of European origin. Certificates of origin can be provided upon request.

All our plastics and polymers are recyclable.

We choose motors from the most recognized manufacturers in Europe and have them adapted to meet specifications that are much more demanding than those of their standard manufacture.

During the development phases, the performance of all our aeration equipment is modelled and then tested, first in our test laboratories, then in partnership with IRSTEA (Institut de Recherche en Sciences et Technologies pour l’Environnement et l’Agriculture) in accordance with standard NF EN 12255.

EUROPELEC R&D department is also working on the constant improvement of existing products, often in partnership with higher education and research institutions such as ENSAM in Paris, or schools of the INP group.

Between 2017 and 2019, all EUROPELEC aerators have undergone major optimizations that have increased their efficiency and reliability. This is particularly the case for the Aquafen high-speed turbines and the SOFIE submerged turbines.

In partnership with IRSTEA

In partnership with ENSAM

Please fill in the following form to upload documents.

Share