EnviroPrep

Compact pretreatment unit

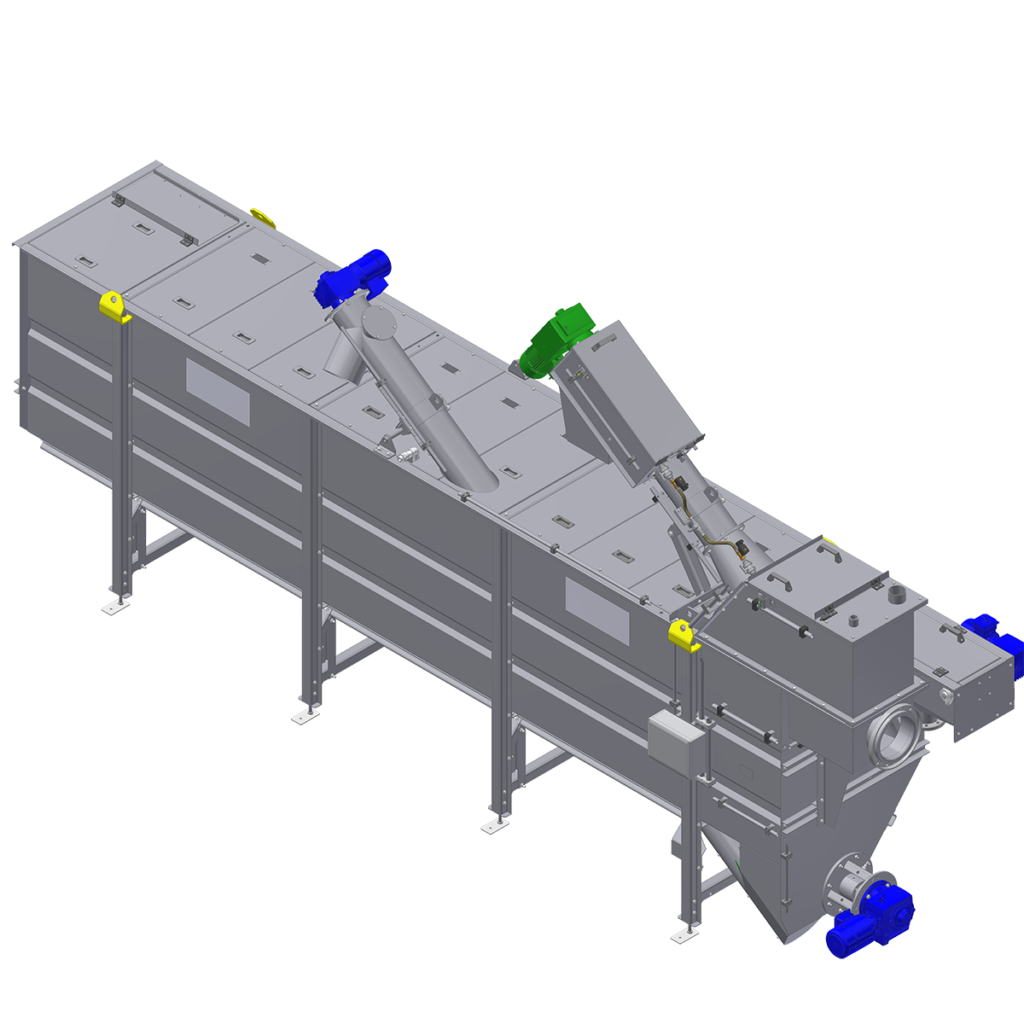

The compact preatreatment unit EnviroPrep are machine-welded in stainless steel with three fucntions, screening, sand removal, and fat removal of raw effluents. Enviromax units are designed to accept flows from 10 up to 500 m3/hr, but several units can be installed in parrallel to accept flow variation due to seasonality or to higher flow. An efficient screening is performed with a Spirascreen adapted to each model. Sand and fat removalis performed inside a longitudinal tank in continuation to the screening phase.

1

5

1

2

3

4

5

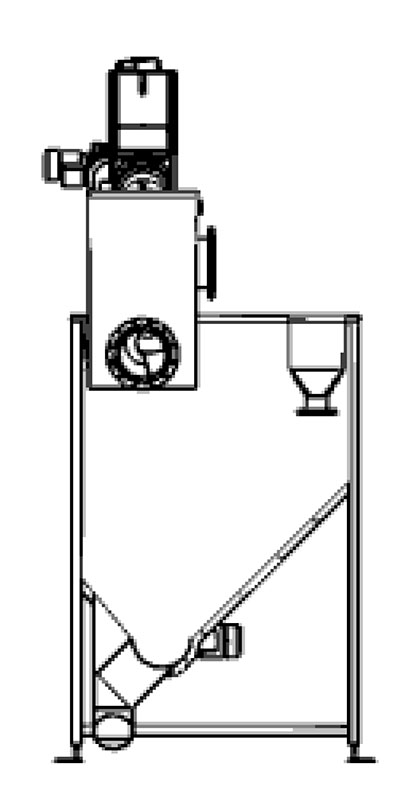

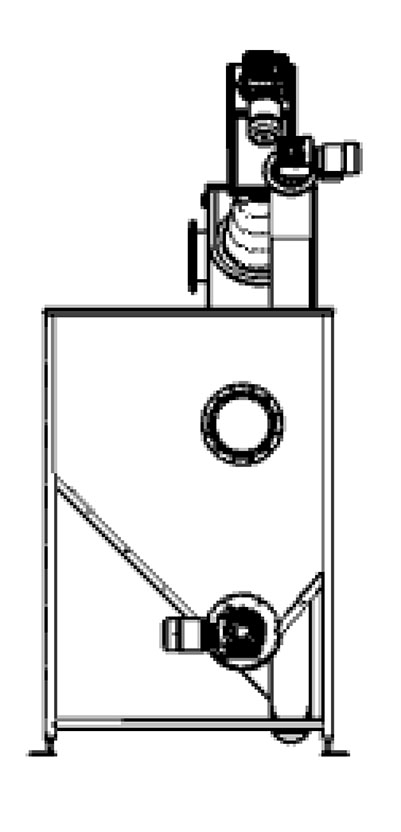

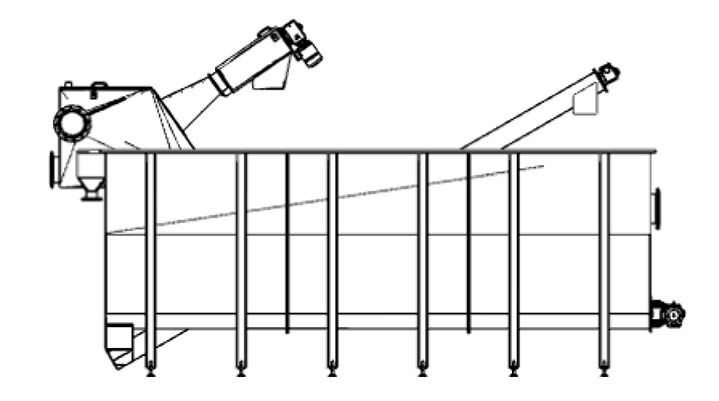

Layouts

1

Fat outlet

2

Effluent inlet

3

Solid waste

4

Sand outlet

5

Treated effluent outlet

Application

The compact preatreatment unit EnviroPrep are designed for urban and industrial raw effluents. Such simple and efficient solution fits perfectly with projects looking after minimizing the concrete and reducing the preatreatment operating costs of urban and industrial sewage treatment plants.

Specificities

- Compact and modular closed unit

- Installation and commissioning: 3-5days

- No civil-work (slab only)

- Lower capital and maintenance costs

Screening and compacting

The solids are retained by the grid and then extracted and conveyed by the screw to the compaction zone. The compaction can be integrated into the screening machine, or carried out by an Enviropac transversal compactor equipped with an innovative and specific back pressure system to adjust the dryness.

Filtration screen

The bubbles formed by an air insufflation ensure the separation of the fat by flotation and separate the organic materials stuck to the sand. The sand and fat removing tank is designed by modules of identical lengths. This modularity offers a great flexibility. It is thus possible to vary, at the origin or later on, the length of the tank to adapt to the desired hydraulic speeds.

Fat extraction

The extraction of fat takes place over the entire length of the machine by means of a longitudinal box. The accumulation of fat in this zone is favored by the movement created by the insufflation of air. The fat is recovered and evacuated by a surface scraper.

Sand extraction

The decanted sand is collected by a first horizontal screw installed at the bottom of the tank, and is transferred to an extraction and draining screw for evacuation towards storage systems before final disposal.

Performances

| Flow rate (m3/h) | |||||

|---|---|---|---|---|---|

| MODEL | EVS5- 300 | EVS5- 400 | EVS5- 500 | EVS5- 600 | EVS5- 680 |

| SAND CAPTURE RATE: 90% > 200 MICRONS | 110 | 220 | 350 | 530 | 750 |

Materials

Construction in stainless steel 304L or 316L

Screw in special steel high resistance

Dimensions

| Overall dimensions in mm | |||

|---|---|---|---|

| MODELS | SMALL | MEDIUM | LARGE |

| LENGTH | ACCORDING TO AFTER | ACCORDING TO AFTER | ACCORDING TO AFTER |

| WIDTH | 1100 | 1500 | 2000 |

| HEIGHT | 3300 | 4100 | 4800 |