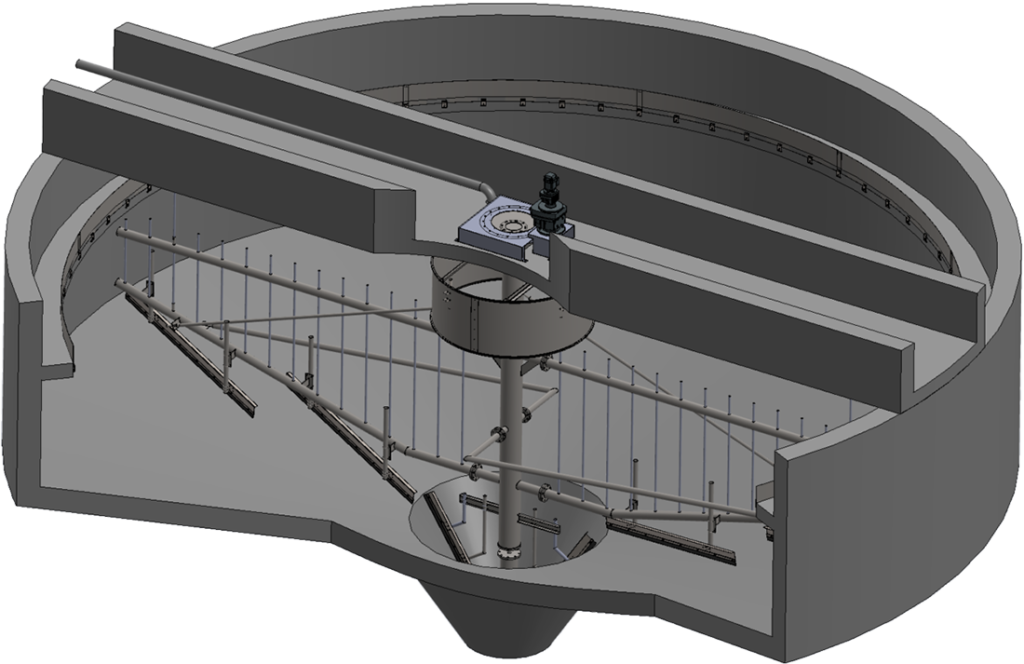

Static thickener

Thickening of sewer station sludge

IP 55 GEARMOTOR

CRANTED DRAINER

For overflow drainage

VERTICAL STAINLESS STEEL HATCH

(304 L or 316L stainless steel) Made up of two arms, spacers and crosspieces, it ensures that the sludge is stirred when turning, thus allowing it to degas and thicken

CLIFFORD

Quieting skirt ensuring uniform distribution of the euent in the thickening zone without turbulence

BOTTOM SCRAPERS

Adjustable to suit the slope of the invert, they lead the thickened sludge to the central collector

DRIVE SHAFT

Central tube supporting the harrow. It is guided in its lower part by a fixed bearing and connected to a drive ring in its upper part

All immersed metal parts are supplied in stainless steel

Low energy consumption

Available in hot-dip galvanised duplex steel on request

Simple and robust equipment, requiring very little maintenance

High durability

- Grade 304L or 316L Stainless Steel available

- Metal walkway

- Possible coverage

- Can be used for hydroxide sludge (especially drinking water)

- Can be used up to 50 metres and more in diameter