EnviroLift

Water lifting

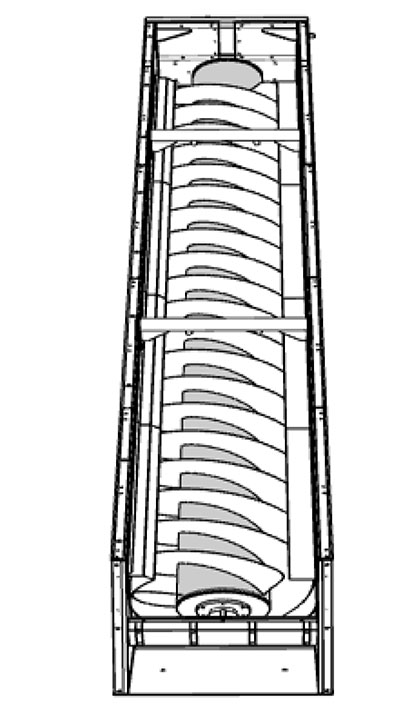

Water lifting screw

Lower bearing

Trough (Option)

Motorisation / Upper bearing

Effluent outlet

Effluent inlet

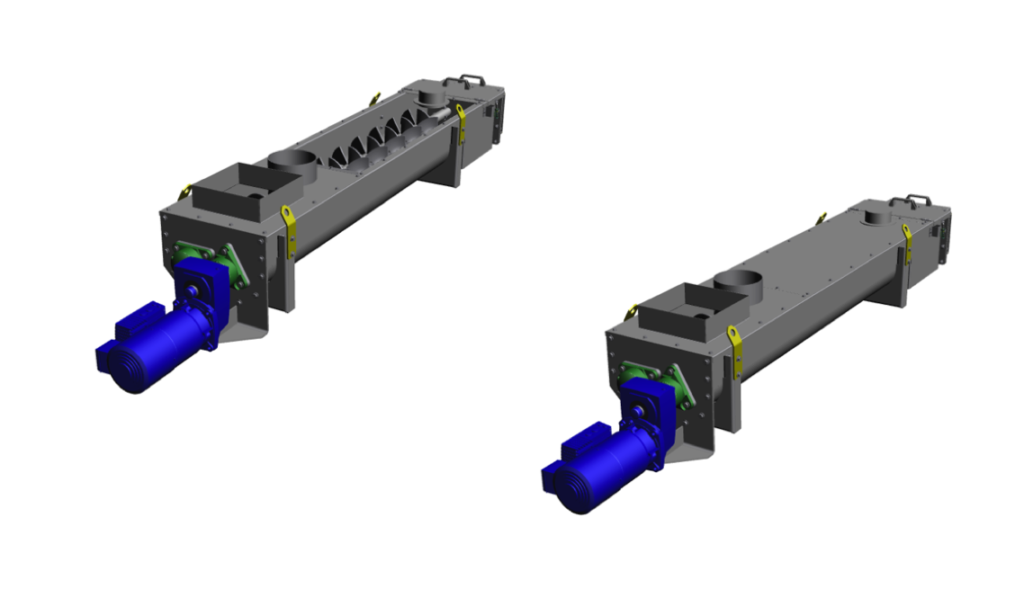

- Large range of flow rates

- Flexible to flow rate variation

- Not sensitive to waste

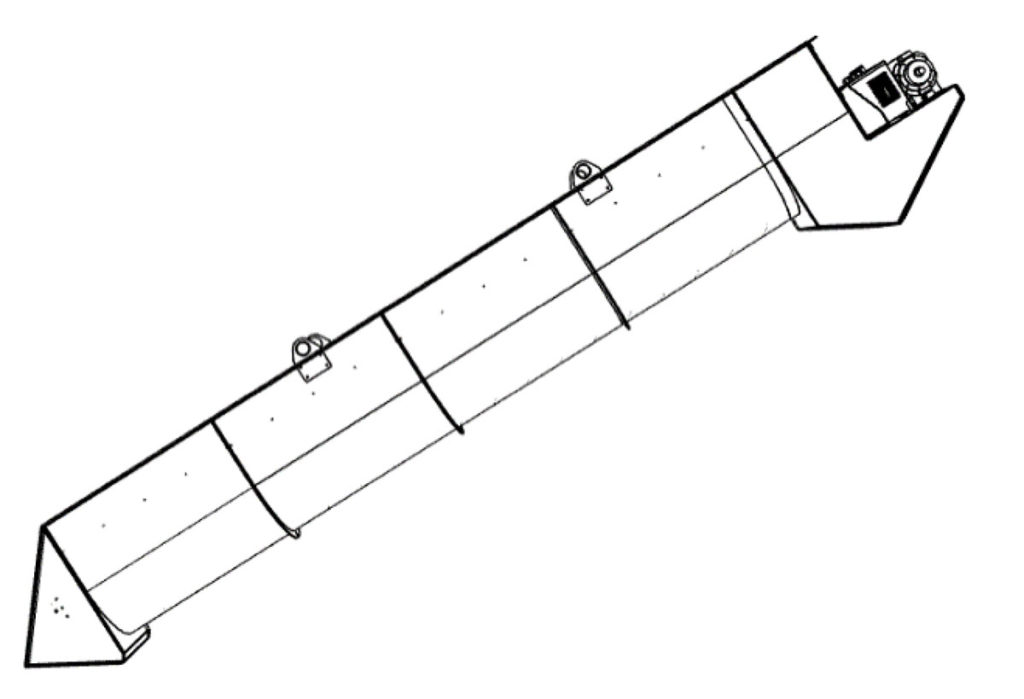

- Design with and without trough

- Up to 3 m diameter and 20 m length

- Lifespan over 30 years

- Low maintenance costs

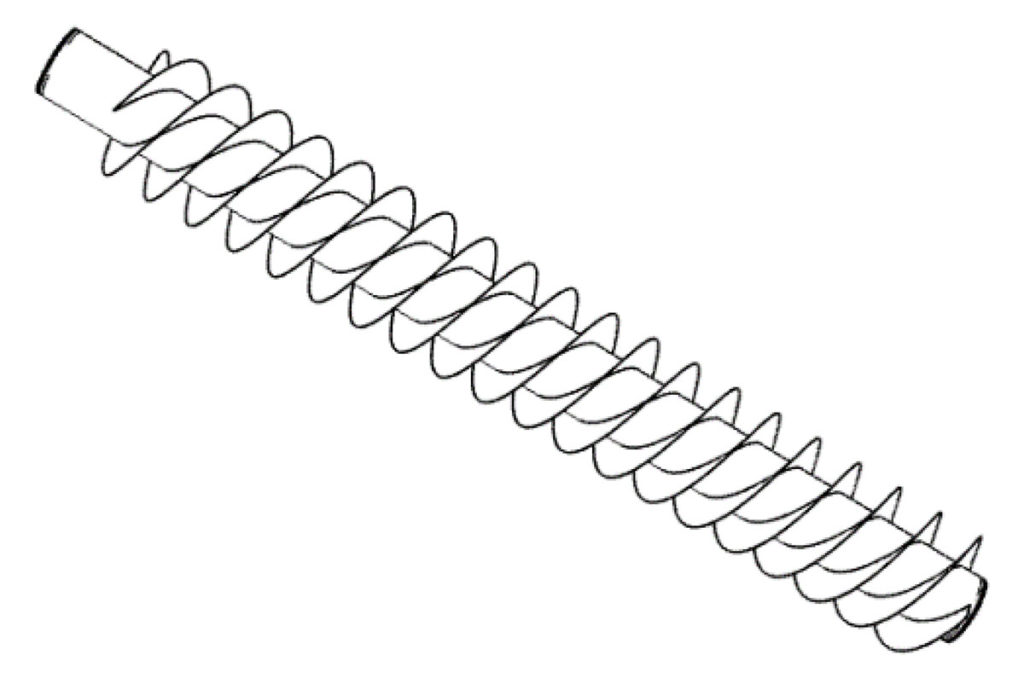

The diameter and the thickness of the central tube are calculated in function of the external diameters, the length and the inclination of the lifting screw, but also according to the number of spirals.

The diameter, pitch, and number of screws are calculated according to the desired flow and height of lift, taking into account the geometry of installation. The screw absorb the flow which arrives at the foot to maintain it to the upper part. This is within the limit of the capacity for which it has been dimensioned. It is a so-called volumetric pump.

The power of the drive unit is calculated in relation to the geometrical characteristics of the lifting screw and its maximum flow. It is an essential component that must be perfectly aligned with the screw axis.

| Flow rates(m3/h) | |

|---|---|

| Models | Diameter from 300 to 3 000 mm |

| Capacity | Up to 11 000 m3/h per unit |

| Overall dimensions in mm | |

|---|---|

| Models | EVM 300 to EVM 3 000 |

| Screw diameter | From 300 to 3 000 mm |

| Length | Lenth up to 20 meters |