EnviroRak

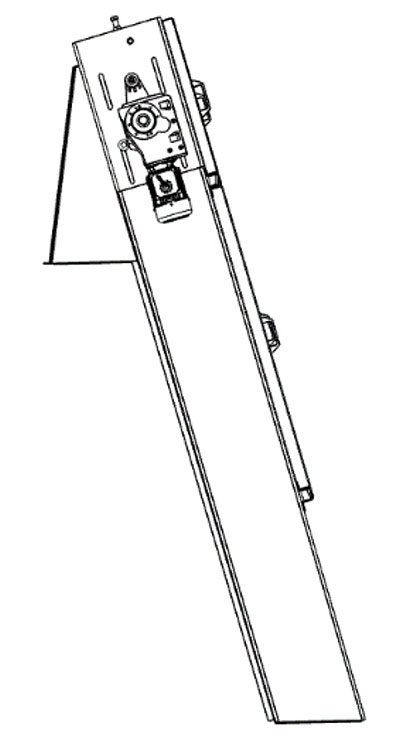

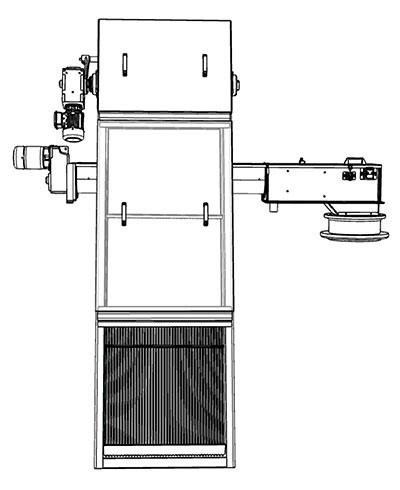

Bar screen

Frame

Inspection cover

Sliding plate

Lateral rake driving chains

Covers

Rake

Solid waste oulet

Motorisation

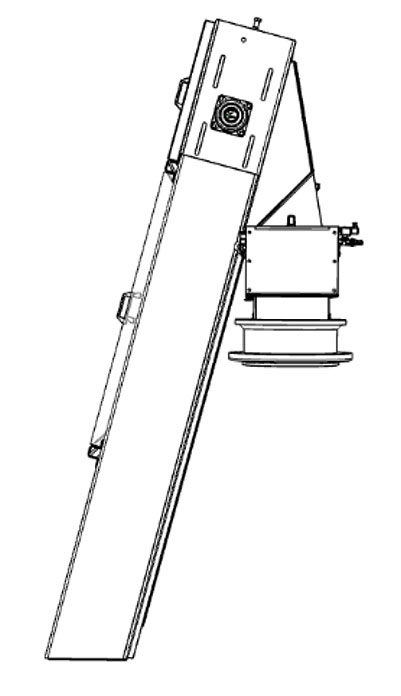

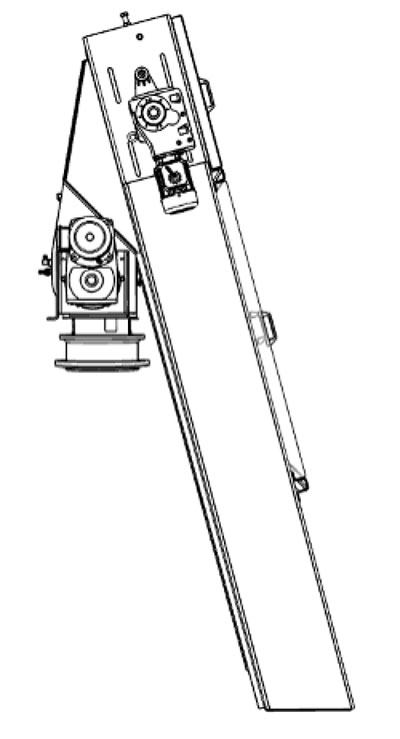

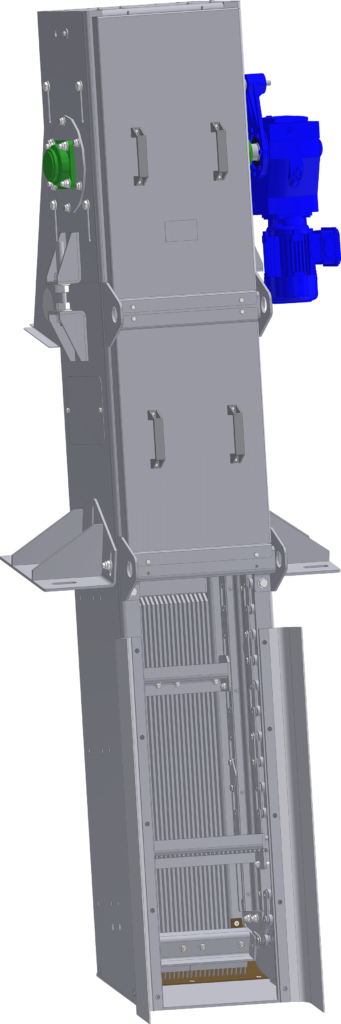

Frame

Inspection cover

Motorisations

Rake

Lateral rake driving chains

Covers

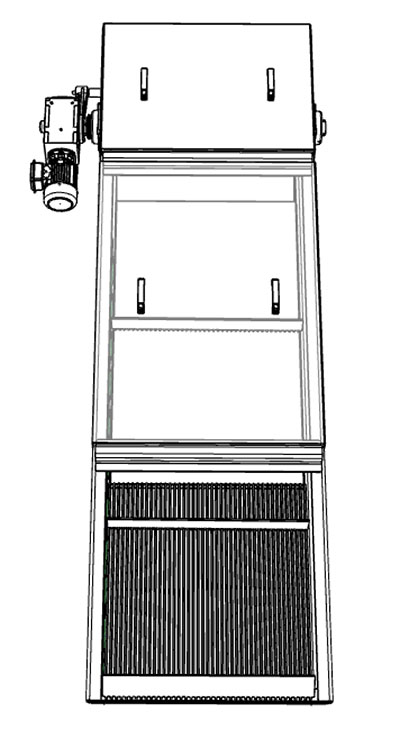

Screw compactor

Bagging unit

Bar screen

The screening waste is falling down directly into an integrated screw compactor installed transversally where it is compressed and dewatered. Screenings can also be conditionned into a continuous plastic bagging unit before beeing dumped into a container.

- Installation : Chanel

- 75° inclined bar screen

- Bar spacing from 3 to 60 mm

- Discharge height up to 8 m

- Screenings discharge downstream

- Rake driving by lateral chains

- Simple design, reliable and sturdy

The structure of the screen is made up of two lateral frame structures fitting the required channel width. For channel installation, lateral rubber bands are sealing the gap between screen and civil-work. Envirorak screens are covering configurations up to 2 meter width and up to 10 meters discharge height.

The screen consists of fixed bars or Johnson profil whose space between them defines the screening mesh. This model with multiple rakes is particularly adapted for high loaded effluent and can be used either as a fine or coarse screen (3 to 60 mm bar spacing).

Rakes are fixed to lateral chains driven by toothed wheels. The precision of the upward movement of the rakes along the bar screen and then along the sliding plate guarantees a perfect scraping and raising of waste up to the point of discharge.

The screening waste can thus be unloaded in a container. They can be also transferred to a conveyor or a transversal screw compactor integrated to the unit (Version RKS/P).

| Hydraulic flow rates with urban effluent (m3/h) | ||||||

|---|---|---|---|---|---|---|

| MESH (MM) | RKS 500 | RKS 750 | RKS 1000 | RKS 1250 | RKS 1500 | RKS 1750 |

| FROM 3 (OR 6 WITH OPTION) TO 60 MM | FLOW RATES ARE DEPENDING OF CHANNEL WIDTH, MESH AND HYDRAULIC PROFILE (FLOW VELOCITY) | |||||

| UP TO 7 500 M3/H | ||||||

Construction in stainless steel 304L or 316L

| Overall dimensions in mm | |||||||

|---|---|---|---|---|---|---|---|

| MODELS | DISCHARGE HEIGHT MAXI | TOTAL HEIGHT | CHANNEL WIDTH MINI | SCREEN WIDTH | MKS WIDTH | CHANNEL HOLD LENGTH MAXI | |

| WITH COMPACTOR | |||||||

| MKS 500 P | 8000 | 9150 | 500 | 370 | 0 | 2500 | 800 |

| MKS 750 P | 8000 | 9150 | 750 | 620 | 0 | 2750 | 800 |

| MKS 1000 P | 8000 | 9150 | 1000 | 860 | 0 | 3000 | 800 |

| MKS 1250 P | 8000 | 9150 | 1250 | 1110 | 0 | 3250 | 800 |

| MKS 1500 P | 8000 | 9150 | 1500 | 1360 | 0 | 3500 | 800 |

| MKS 1750 P | 8000 | 9150 | 1750 | 1610 | 1730 | 3750 | 800 |