EnviroScreen

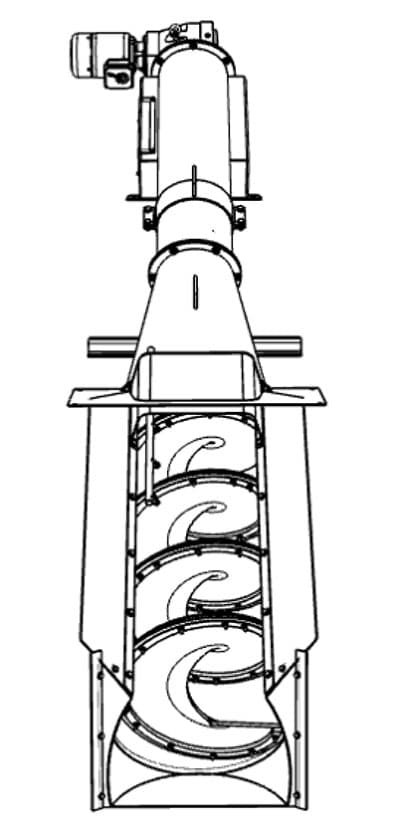

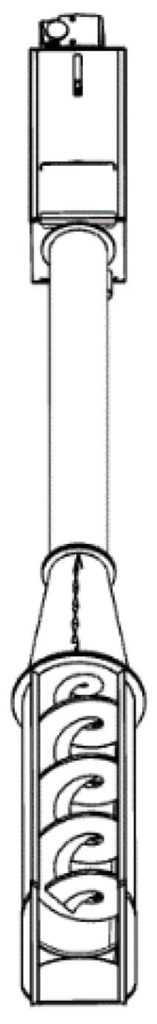

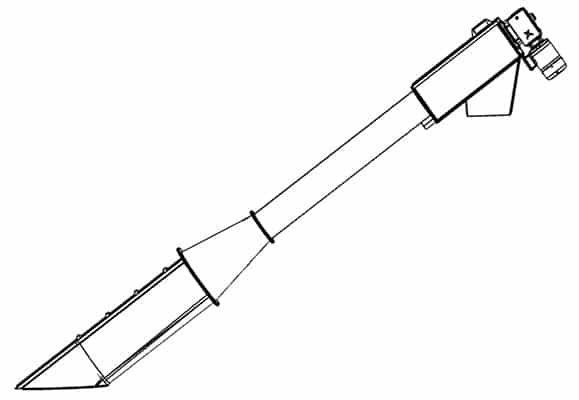

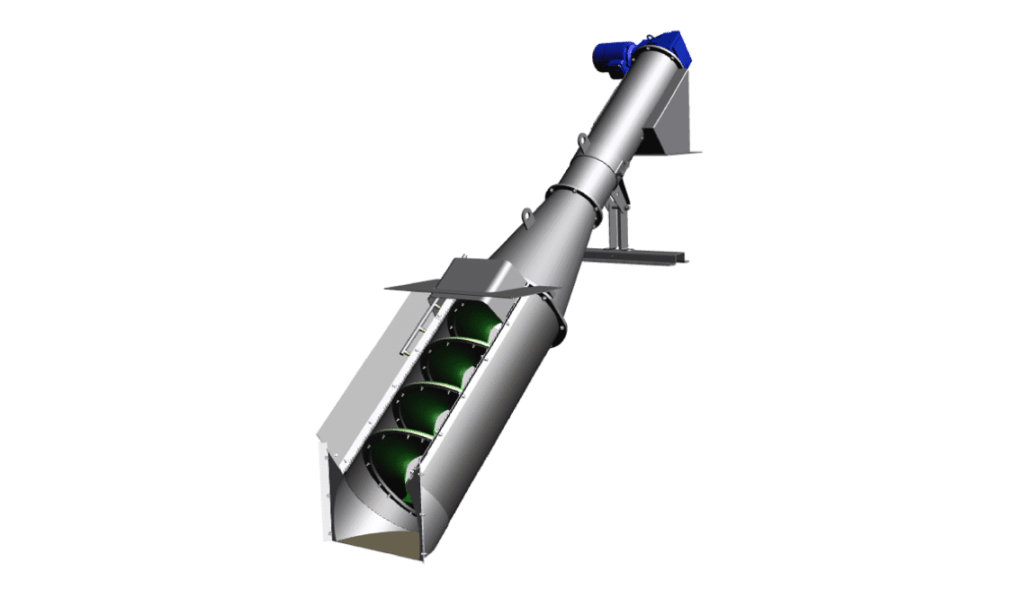

Shaftless screw screening

Discharge zone

Dry waste outlet

Fixing supports

Effluent inlet

Effluent outlet

Motorisation

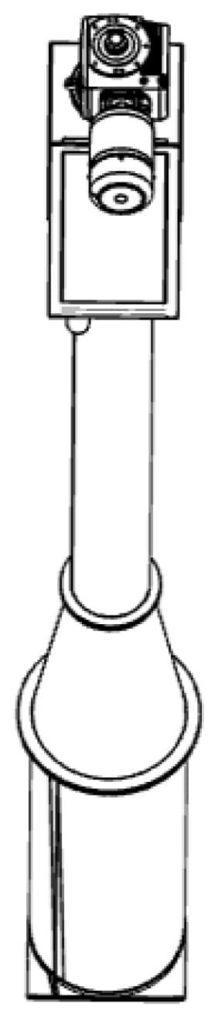

Shaftless screw fitted with brush

Filtration screen

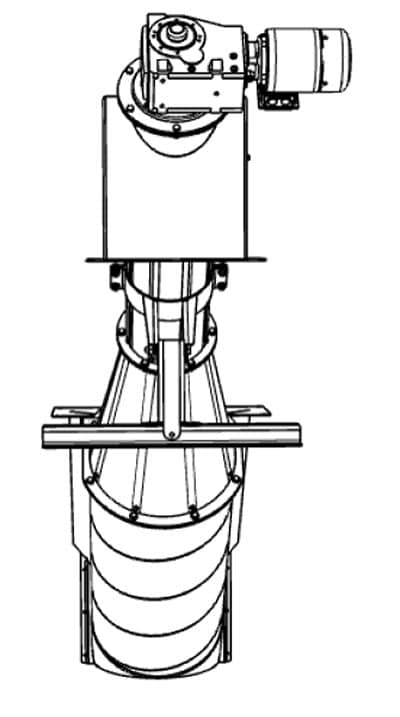

Shaftless screw with brushes

Effluent inlet

Effluent outlet

Compacting zone

Solid waste

Filtration screen

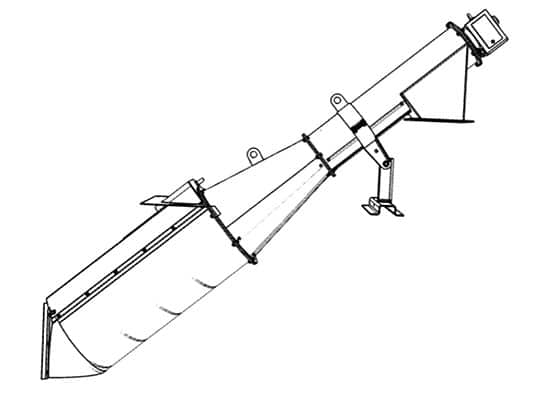

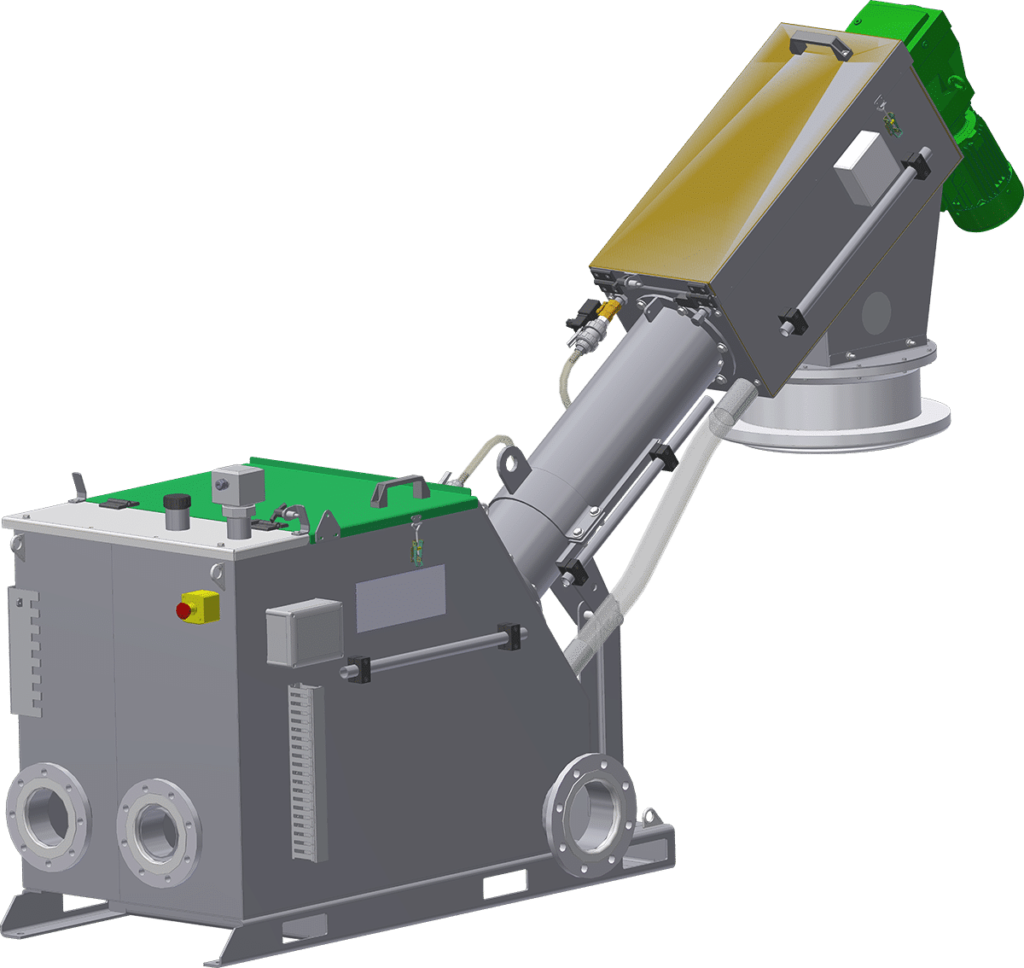

- Easy installation and maintenance

- Small footprint

- Proven technology

- Low maintenance costs

- Reliability and durability

The effluent is processed through the cylindric filtration grid. Due to such design, the effective filtration area is much larger compare to flat screening technology. Therefore, the ratio between size/flow allows to reduce the overall dimensions of the unit. Brushes are fixed onto the shaftless screw in order to keep the filtration zone clean and flow efficient by rotation during operation.

The screening waste can be either discharged directly into containers or conditionned in continuous closed plastic bagging unit.

| Hydraulic flow rates with urban effluent (m3/h) | |||||

|---|---|---|---|---|---|

| MESH (MM) | SRS 200 | SRS 300 | SRS 400 | SRS 500 | SRS 680 |

| 0.75 | 38 | 76 | 121 | 192 | 359 |

| 1 | 47 | 94 | 149 | 237 | 443 |

| 2 | 68 | 136 | 215 | 342 | 638 |

| 3 | 55 | 110 | 174 | 277 | 517 |

| 6 | 68 | 136 | 215 | 342 | 638 |

| 10 | 84 | 168 | 266 | 422 | 788 |

Construction in stainless steel 304L or 316L

Screw in special steel high resistance

| Overall dimensions in mm | ||||||||

|---|---|---|---|---|---|---|---|---|

| Models | SRS 200/300 / P | SRS 400 / P | SRS 500 / P | SRS 680 / P | ||||

| Dimensions | Mini | Maxi | Mini | Maxi | Mini | Maxi | Mini | Maxi |

| Unit length | 2500 | 9000 | 3000 | 9000 | 3000 | 9000 | 3000 | 9000 |

| Footprint | 2048 | 7372 | 2457 | 7372 | 2457 | 7372 | 2457 | 7372 |

| Height | 1434 | 5162 | 1721 | 5162 | 1721 | 5162 | 1721 | 5162 |

| Width | 250 / 350* | 450 | 550 | 750 | ||||

*350 with shaftless screw SRS/P